Hemp vs. Marijuana:

It all starts with cannabis. CBD occurs naturally in some cannabis, but not in all cannabis. As an example, Marijuana sometimes contains decent levels of CBD. The majority of strains contain trace amounts of CBD though, if any. If a marijuana strain contains no CBD, then there’s no CBD to extract.

Hemp on the other hand usually contains at least some CBD. The percentage varies from single digits to over 20% by dry weight. So logically, starting with good genetics that actually contain CBD paves the way to make viable CBD products.

What to expect:

Most CBD products on the market today come from Hemp. New Hemp laws in the United States have made it a popular source for CBD due to loosened restrictions. Customers throughout the country can purchase Hemp-derived CBD products since they can be shipped anywhere. Marijuana-derived CBD products though, must comply with individual state laws concerning the purchasing and use of Marijuana products.

The process of processing:

Choosing your source:

The flowers/buds of female cannabis plants tend to make the best CBD extract. This part of the plant contain the highest concentration of cannabinoids such as CBD. It also contains the highest concentration of other beneficial compounds known as Terpenes and Flavonoids.

Washing:

Once the crop is harvested and dried, the CBD can then be extracted using solvents. Extractors refer to this part of the process as the “wash”. During a “wash”, solvents pass over the cannabis flower, separating beneficial cannabinoids and compounds from the plant matter.

Solvents include Butane, Propane, Hexane, Heptane, CO2, Naphtha, ISO, and others. Arguably, organic sugarcane ethanol (drinking alcohol) trumps the others. It draws out greater varieties and concentrations of beneficial compounds from the plant than other extraction methods.

Evaporating:

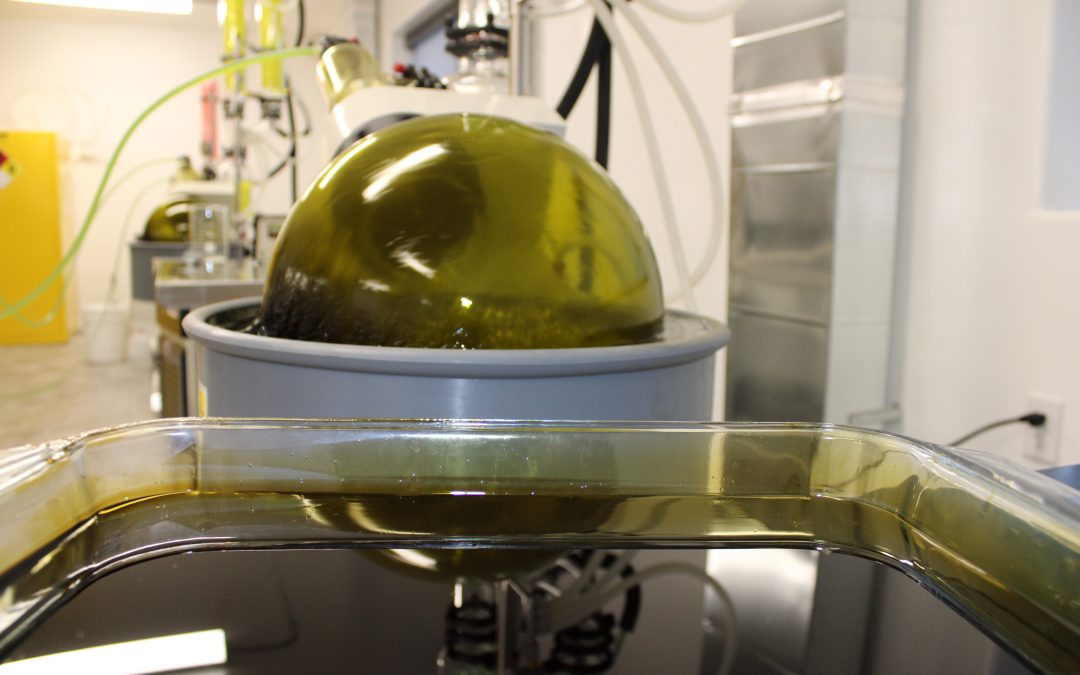

After the wash, solvents need to be evaporated out of the hemp extract. This involves pouring the extract into rotary evaporators (rotovaps, pictured at the top of the page). These machines vacuum seal the product, allowing solvents to evaporate at lower temperatures. Maintaining that low temperature preserves the integrity of molecules from the plant.

Efficient labs reclaim a good portion of their solvents to avoid waste. Once solvents evaporate from the extract, they condense and collect in sterile basins for reuse.

Decarboxylating:

After running the extract through the rotovap, the oil is then decarboxylated and transformed from CBD acid into the CBD oil we consume. The best extracts contain other cannabinoids and beneficial compounds as well as CBD.

Buyer Beware:

It should be noted, some solvents are harmful, and no extraction process completely purges those solvents. That’s why it’s wisest to purchase products made from clean, safe extraction methods. Solvents like Butane and Hexane poison the body, and other compounds like CO2 don’t extract as effectively.

With all the variables involved, CBD oils vary greatly in quality and safety. So choose companies that not only have certified 3rd party lab analyses, but also companies that explain their process. Inform yourself thoroughly so you can navigate the world of CBD with confidence.